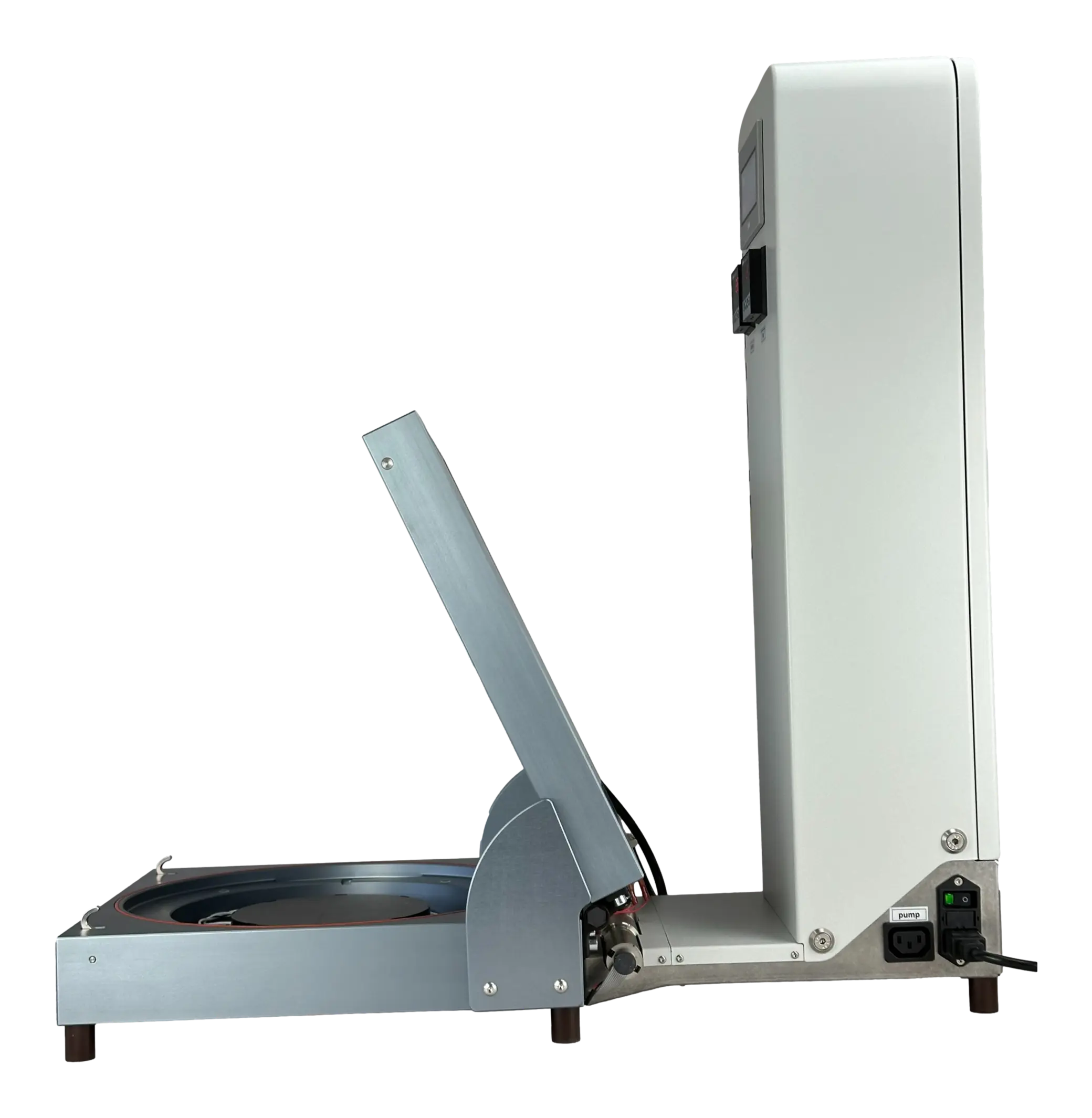

Semi-Automatic Silicon Carbide Wafer Mounter V-150 SiC

Engineered for performance and control, this device delivers fully automated core processes for the highest level of repeatability by leveraging:

- Heated top and bottom chucks with independent temperature controls

- A compact vacuum chamber that operates under 5 millibars of pressure

- Fully customizable process steps durations to fully control temperature gradients

- "Recipe" feature to save up to 10 favorite programs

| Wafer size: | up to 6" |

| Wafer type: | flat surface |

| Wafer thickness: | 80µm to 3mm |

| Maximum temperature: | 150°C / 300°F |

| Frame size: | Ø8" DTF 2-8-1 (on request) |

| Width: | 402 mm |

| Depth: | 670 mm |

| Height: | 686 mm |

| Weight: | 46 kg |

| Vacuum required: | 2 mbar absolute, at least 16m3/h |

| Pressure required: | 4-8 bar |

| Cooling Water requirement: | up to 4 bar, 10-20oC |

| Power input: | 110-240 VAC |

| Peak power consumption: | 920 W |

| Clean room application: | in use up to ISO 4 - 5 |

| Certification: | CE Certified, IEC 204-1 safety standards |

Manufactured and developed in Switzerland, the V-150 SiC Wafer Mounter from Powatec is the ideal device for precisely mounting Silicon Carbide wafers, sensitive or broken wafers, and curved wafers onto 6-inch dicing frames in a heated process.

Key Features

A unique setting of the V-150 SiC mounter is the adjustable duration of the mounting step. This setting ensures that the contact surface between the tape and wafer reaches a predetermined temperature when pressed together before moving on. This not only generates an extremely high-quality mount, but it also makes the process highly repeatable and consistent.

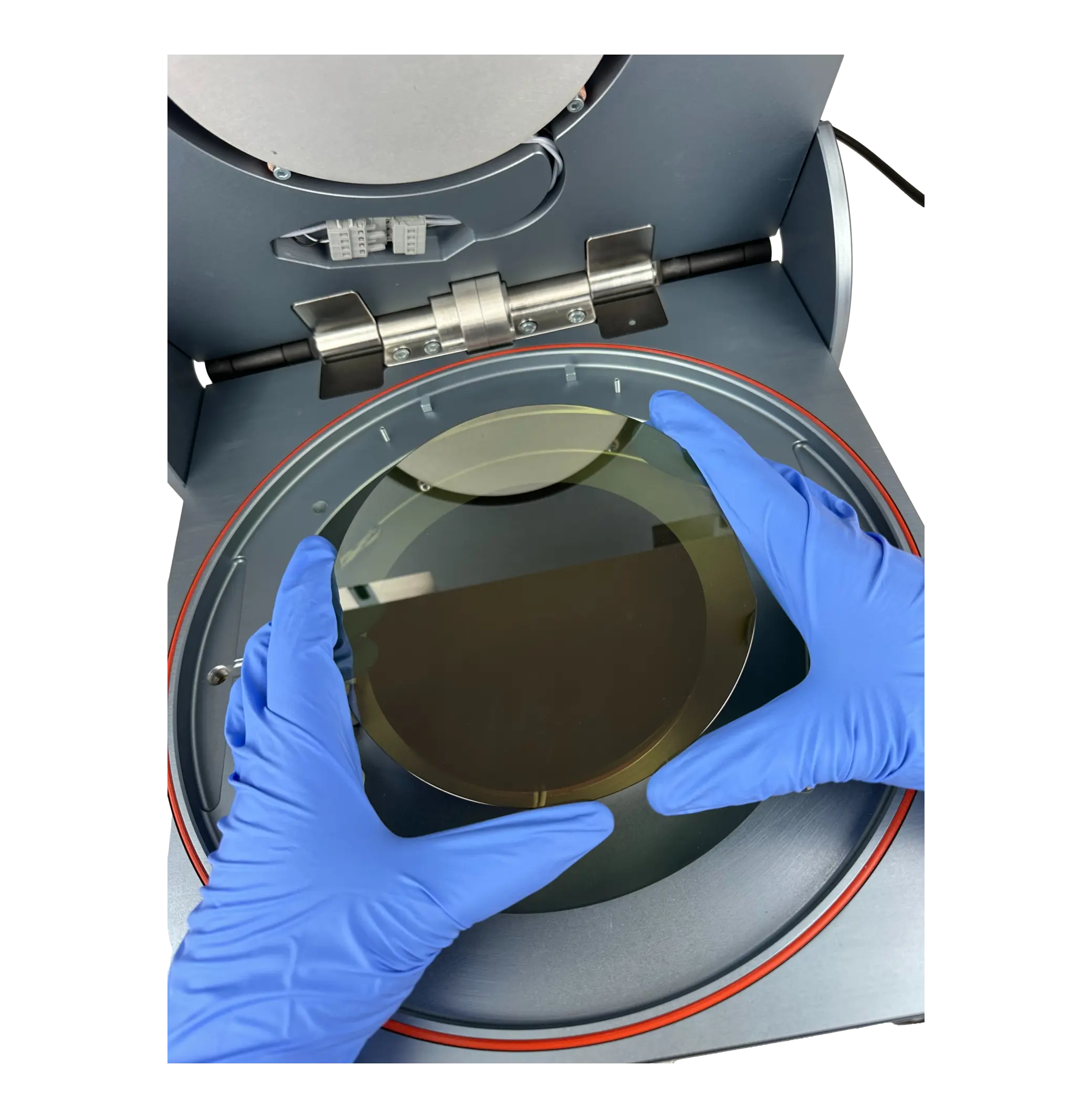

At the heart of the device is its precision-controlled vacuum chamber, which ensures an environment that optimizes wafer placement and adhesion, reducing defects and improving yield.

Operation

- Place the wafer and tape-mounted frame into the chamber and set the desired temperature for each chuck, up to 150°C.

- Once the "start" button is pressed, the device will proceed to execute the user-defined process steps automatically.

- After pre-heating is complete, a vacuum is quickly created in the chamber and the wafer, frame, and tape are brought into contact with each other free of any air enclosures.

- The tape and wafer are brought together at two different temperatures, so the device will hold the stack together for a period until the ideal temperature gradient is reached by the contact surface.

- The mounted assembly is then lowered to the original position, the chamber is refilled with air, and the device opens the chamber for the removal of the sample.

Flexibility

The device’s flexibility allows the user to even control the duration of the pre-heating step, the speed at which the chamber opens and closes, the speed at which the bottom chuck lifts and lowers, and the force used to press the wafer and tape together.

Accessories

Vacuum Pump (up to ISO 6 clean room)

0.55 kW, 110-240 V, 50/60 Hz. Adapted and commissioned by POWATEC for seamless operation with the V-Series products. Allows thereby high clean room class application.

Vacuum Pump (up to ISO 1 clean room)

0.55 kW, 110-240 V, 50/60 Hz. Adapted and commissioned by POWATEC for seamless operation with the V-Series products. Allows thereby high clean room class application.

0.55 kW, 110-240 V, 50/60 Hz. Performance optimized for use with the V-150 SiC. Supplied with a active carbon filter and gas particle absorber developed by POWATEC. Allows thereby clean room application up to ISO 6.

For inquiries on these products or customizations, please contact Powatec for full details.

Downloads

Coming Soon

FAQs

Can POWATEC perform sample tests?

YES. If you are seriously interested in acquiring a V-150 SiC, but would like to have it tested with your own samples first, then we can offer a free sample testing at our facility. We also support you in the selection of suitable tapes/films, offer free dicing or UV curing, and support you to select the most suitable parameters for your application. Furthermore, as a proof of record, we can offer a live stream or video recording to document your samples being processed with the device. Alternatively, we are more than happy to welcome you to visit our facility for an in-person demonstration.

Does the V-150 SiC also mount the tape to the frame?

NO. To use the V-150 SiC, it is necessary to first mount the tape to the frame. It is therefore recommended to have either a POWATEC Manual Wafer Mounter (P-200), or a Frame Mounter (FM-200). However, any other wafer mounter on the market should be able to prepare the tape on the frame.

What is the minimum wafer thickness the device can support?

The minimum wafer thickness on the standard device is 80µm.

What is the maximum thickness of the wafer?

With the standard chuck it is possible to mount wafers up to 3mm in thickness and structures/bumps with a maximum height of 170µm. Larger dimensions are possible with a simple customized design.

Do I need to make adjustments for different wafer thicknesses?

NO. No adjustments are needed, which is a great advantage of the V-150 SiC.

Is this device only suitable for Silicon Carbide wafers? Or can it be used for other types as well?

The V-150 SiC is suitable for any application and wafer material that requires a high quality mount with tight process controls and the flexibility to heat the wafer and tape at different temperatures. The tool was originally developed for a Silicon Carbide fab, hence the name, but it is not limited to any specific material.

Video

Contact us

Related Products

Manual Wafer Mounter P-200

Suitable to mount wafers/frames up to Φ8" with tape

Standard UV Curing System U-200

Suitable for wafers/frames up to Φ8

8″ Dicing Frame Magazine, 25 Slots

25-Slot Magazine, material is solid aluminum